⚙️ Elevate Your Motor Control Game — Precision, Power & Protection in One Drive!

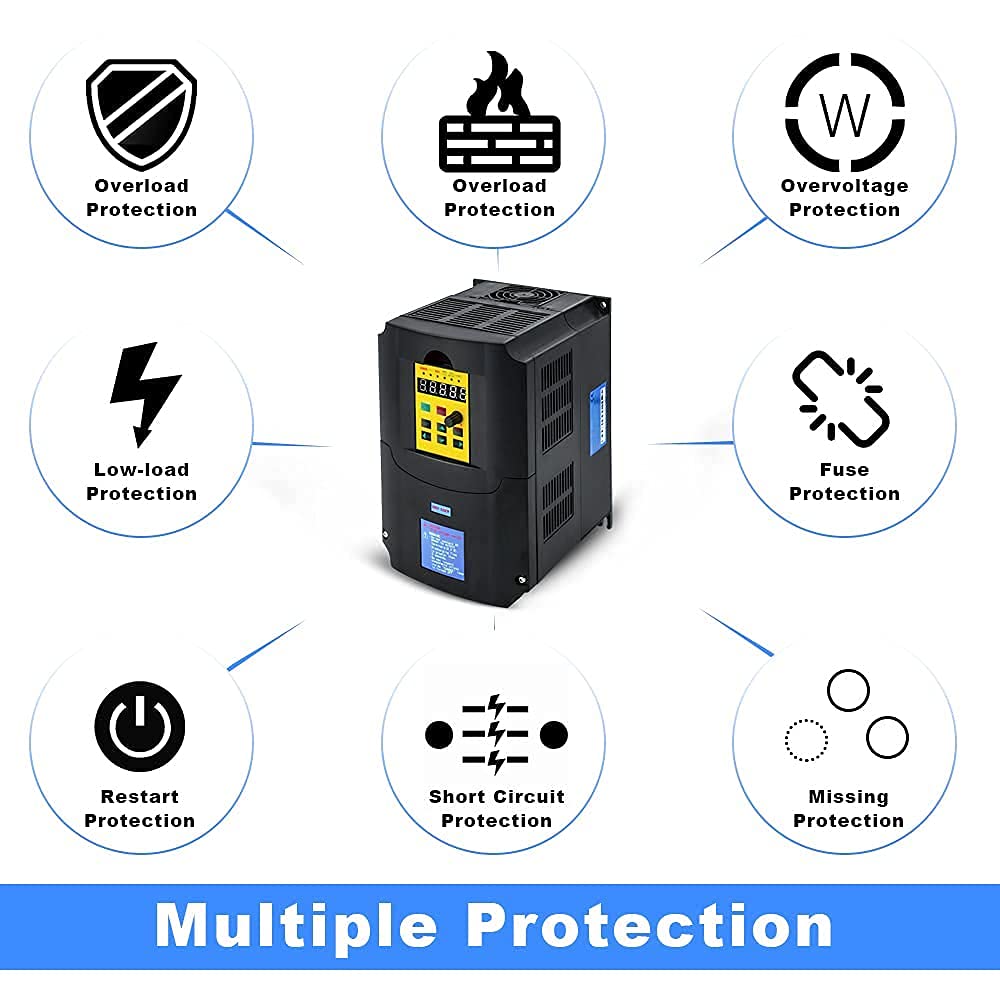

The VFD 4KW 5HP 220V Variable Frequency Drive Controller delivers high-performance vector control with a wide 0-400Hz frequency range and 26A output current. Compatible with single or three-phase input and designed for CNC motors, compressors, and spindles, it features intuitive digital controls, comprehensive multi-layer protection, and low-noise operation for reliable, long-lasting industrial motor speed management.

| ASIN | B09C5NDXDG |

| Antenna Location | Compressor, CNC router, Spindle motor, Grinder, Mixer, Slitter, Conveyor, Treadmills, Centrifuger, Lathe, Extruder |

| Best Sellers Rank | #99,852 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #26 in Motor Drives |

| Brand | HKS |

| Built-In Media | VFD |

| Customer Reviews | 4.0 out of 5 stars 154 Reviews |

| Display Type | digital |

| Electrical Output Waveform | Pure Sine Wave |

| Frequency | 400 Hz |

| Included Components | VFD |

| Input Voltage | 220 Volts |

| Inverter Capacity Volt-Amp | 18182 |

| Item Weight | 5.68 Pounds |

| Manufacturer | HKS-AISAICON |

| Model Name | VFD 4KW 5HP 220V 1 or 3 Phase Input 3 Phase 0-400HZ Output 26A Variable Frequency Drive Controller |

| Model Number | 87e78d64-51b3-4433-9664-8f61bda3572b |

| Output Power | 4 Kilowatts |

| Output Voltage | 220 Volts |

| Peak Output Power Watts | 4000 |

| Power Source | 220v,Vfd |

| Recommended Uses For Product | Compressor, CNC router, Spindle motor, Grinder, Mixer, Slitter, Conveyor, Treadmills, Centrifuger, Lathe, Extruder Recommended Uses For Product Compressor, CNC router, Spindle motor, Grinder, Mixer, Slitter, Conveyor, Treadmills, Centrifuger, Lathe, Extruder See more |

| Standby Power Shutoff | 90 |

| Voltage | 220 Volts |

| Wattage | 4 KW |

R**R

excellent product

Excellent, it works perfectly. I used it for my cylinder head grinding machine and it worked without any problems.

J**H

Works great and support was very helpful!

I use this to add a 2nd and 3rd phase to be able to run my 3 phase air compressor. I reached out to their support before I bought it and they were very helpful. They wanted a picture of the data plate from the motor and had their engineers review to recommend which size I should get. I mentioned to them that it was for an air compressor and they even provided instructions to set it up to work with my pressure switch! I would highly recommend this VFD if you only have single phase and want to run a 3 phase motor. (Ignore my wiring. I tried another VFD first and ran 10/3 with a 30A breaker. When I switched to this one I ran 8/3 (you can use 8/2 though) with a 40A breaker. I just haven't tidied it up yet. )

J**Y

No strain relief for the AC line input wires nor the motor output wires.

I bought this VFD to replace the Westinghouse/TECO N3 VFD which failed on my 2HP Bridgeport milling machine. I think the unit is actually the ISACON A2 Series, I'm not sure if HKS rebrands it or if HKS is part of ISACON? This unit is considerably smaller than the TECO N3 and only has 2 mounting holes. There is no strain relief for the AC line input wires nor the motor output wires. I used the strain relief bracket off of the TECO, but this still leaves the wires exposed. I took off one star for no strain relief. I'd also prefer it if all the wires were completely enclosed. With the wires exposed, I'm not sure if this unit meets US UL wiring code or not? The terminals for the AC line input and motor output are also quite small, I used forked terminals for a US #6 stud (or you could use whatever the metric equivalent is), this means you'll probably have to use #12 GA wire or less. I followed the instructions given in the "Set The Initial Test Parameters" found on the Amazon page for this unit, I just changed the PN02, PN10, and PN12 parameters to 60Hz instead of 50Hz (I'm in the USA). The instruction manual is very brief but adequate for what I needed, but could be better explaining some of the more advanced features. The turn on and turn off acceleration default to 10S and are much slower than the TECO unit, but these can be easily changed with PN08 and PN09. I used an external pot on the TECO N3 to change the frequency and thus the motor speed, but this can be done on this unit with the UP/DOWN buttons on the front panel, which is nice feature. You can also set it up to use an external pot if you want to. Initially I like the way the unit works, the front panel seems fairly intuitive, and everything worked as I expected. The price is certainly appealing, much cheaper compared to something like the TECO. It will be interesting to see how it holds up in the long term, but I would certainly recommend it at this point especially for a home machinist such as myself.

R**Z

would not recommend

junk right out of the box. parameters would not stay set and could not turn unit off with stop button.

R**Y

It work fine

It works fine but the instructions for the settings are unclear

T**N

Easiest VF

They arrived and worked. I had these old molloms, these were less complicated and easier to use, with clearer labeling for the one phase power connectors. Both worked for my purpose. I returned them, but only because the owner of the building I was in offered to pay for them to replace one of the broken ones.

D**H

Remote switch inputs do not allow acceleration control

I have purchased two of these units, for different machines. Both VFDs exhibit the same issue. The acceleration parameter works when the unit is set for panel control, but when set for start/stop by external switch closure, acceleration time is ignored, leading to an instantaneous start and overcurrent error when starting. (BTW, I've set up many VFDs, this is not an operator error). There is no tech support available. This severely limits how the unit can be installed and used. I will not buy from this manufacturer again.

A**.

Don't expect this to run your 1 hp motor.

I bought two of these, one for a .5/1/0 hp motor, one for a 1/4 hp motor. After pondering the translations in the manual, I was able to get both units set up and running. In the case of the .5/1 hp motor, the drive complained of overcurrent during acceleration. After fussing with the torque boost and increasing the acceleration time, I was able to get the unit to operate without error using the .5 hp winding at 20 seconds acceleration, but not the 1hp winding. My conclusion is that while the drive may be capable of operating at 1hp (750W, 4.2 amp/phase) it is incapable of supplying the additional current for startup... I kept the unit operating the 1/4hp motor and returned the second unit in favor of a WEG CFW300 1hp unit, which, although the parameter setup is a bit arcane, worked flawlessly right first time with 2 seconds of acceleration to 60 hz.